Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

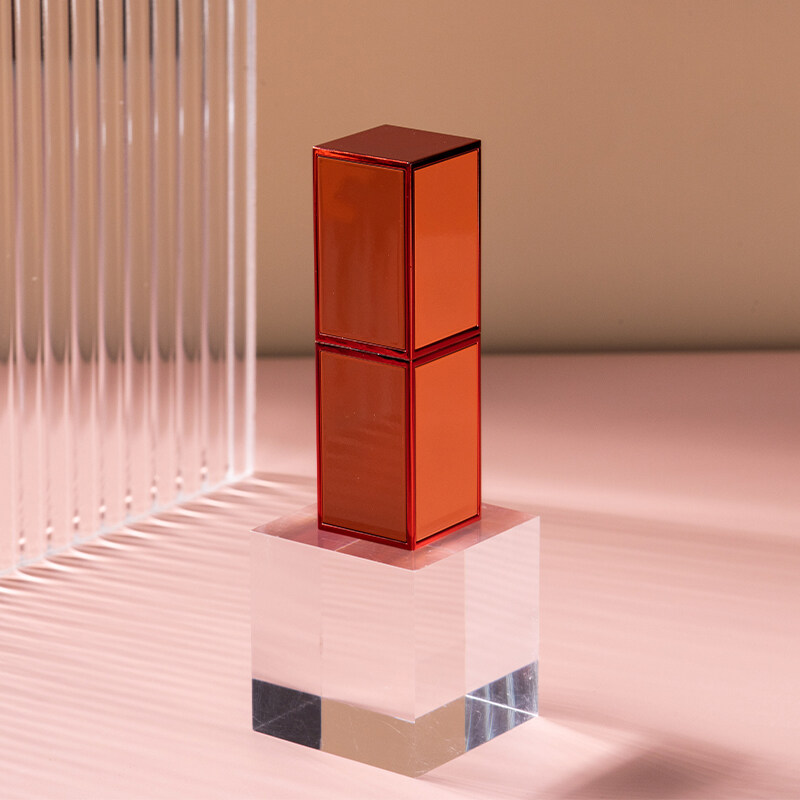

In the vibrant world of cosmetics, where every shade and shimmer tells a story, the humble lipstick tube often goes unnoticed as a mere vessel for the alluring hues it contains. But step inside a lipstick tube factory, and you'll discover a world brimming with precision, creativity, and a touch of magic that brings these tiny containers to life. Today, let's embark on a colorful journey through the heart of a lipstick tube factory, where the art of beauty meets the science of manufacturing.

The Spark of Inspiration

It all starts with a spark of inspiration—a fleeting thought, a trending color, or a client's vision. Designers and marketers gather around a table, sketching, discussing, and refining concepts that will eventually grace the shelves of beauty boutiques worldwide. From sleek matte black to glitzy holographic, the design process is a fusion of form and function, ensuring that each lipstick tube not only looks stunning but also feels comfortable in the hand and enhances the overall user experience.

Molding the Future

As the designs are finalized, the real magic begins in the production line. Aluminum, plastic, or a combination of both materials are carefully selected based on sustainability, durability, and aesthetic appeal. These raw materials are fed into advanced injection molding machines, which under intense pressure and heat, transform them into perfectly shaped lipstick tubes. The precision is astounding; each tube emerges with seamless lines and a glossy finish, ready for the next stage.

Colorful Coatings

Once the tubes are formed, they undergo a transformation that adds a layer of vibrancy. The coating process involves applying a thin film of lacquer or paint that adheres to the surface, giving it that signature shine or matte finish. Colors are mixed with meticulous care, ensuring that the final product matches the desired hue exactly. Some factories even offer customization services, allowing brands to create exclusive shades that stand out in a crowded market.

Decorative Details

The lipstick tube factory is also where the finer details come to life. Embossing, laser engraving, or even hand-applied glitter can be added to enhance the tube's appearance. Logos, patterns, and text are carefully placed, turning these simple containers into brand ambassadors. The attention to detail is remarkable; each tube is inspected under bright lights to ensure perfection before moving on to the next stage.

Functional Mechanics

But lipstick tubes aren't just about looks; they must also function flawlessly. Mechanisms for the base, click-to-open caps, and even twist-up mechanisms are precision-assembled. Springs, hinges, and other components are carefully fitted to ensure a smooth and satisfying user experience. Some factories even incorporate innovative features like magnetic closures or built-in mirrors, elevating the lipstick experience to new heights.

Quality Control and Beyond

Before leaving the factory, every lipstick tube undergoes rigorous quality control checks. This includes visual inspections, dimensional measurements, and even drop tests to ensure durability. Only when a tube meets the highest standards does it earn the right to hold that precious lipstick inside. And even then, the journey doesn't end there; feedback from end-users is continuously analyzed to inform future designs and improvements.

A World of Possibilities

As we conclude our tour through the lipstick tube factory, it's clear that these tiny containers hold a universe of possibilities. They're more than just vessels; they're expressions of creativity, innovation, and the relentless pursuit of beauty. From concept to creation, the process is a testament to the dedication and craftsmanship of those who bring these tiny wonders to life. So, the next time you swipe on your favorite lipstick, take a moment to appreciate the journey it took to get there—a journey filled with color, precision, and the unwavering passion for making beauty accessible to all.

Sustainability in Mind

In today's eco-conscious era, sustainability is a top priority for many lipstick tube factories. Manufacturers are increasingly adopting eco-friendly practices, from using recycled materials to implementing energy-efficient production processes. Some factories even offer biodegradable or compostable lipstick tubes, minimizing their environmental impact. These efforts not only align with consumer preferences but also contribute to a more sustainable future for the beauty industry.

Customization and Personalization

The rise of customization and personalization in the beauty industry has also had a significant impact on lipstick tube factories. Consumers are no longer satisfied with one-size-fits-all products; they want lipstick tubes that reflect their unique style and personality. Factories have responded by offering a wide range of customization options, including custom colors, prints, engravings, and even the ability to add personal messages or initials. This trend has opened up new avenues for growth and allowed brands to differentiate themselves in a crowded market.

Innovation and Technology

Innovation and technology play a crucial role in the lipstick tube factory. Manufacturers are constantly investing in new equipment and technologies to improve efficiency, reduce waste, and enhance product quality. From advanced injection molding machines to robotic assembly lines, technology has transformed the production process, making it faster, more precise, and more sustainable. Additionally, digital printing and 3D printing technologies have revolutionized the customization process, enabling factories to produce limited-edition or one-of-a-kind lipstick tubes with ease.

Collaboration and Partnerships

Lipstick tube factories often collaborate with designers, makeup artists, and other industry professionals to stay ahead of the curve. These partnerships enable factories to tap into fresh ideas, emerging trends, and consumer insights, resulting in innovative and exciting new products. Moreover, by working closely with brands, factories can ensure that their lipstick tubes perfectly complement the overall aesthetic and messaging of the brand, creating a cohesive and memorable experience for consumers.

The Human Touch

Despite the advancements in technology, the human touch remains an integral part of the lipstick tube factory. Skilled craftsmen and technicians are required to oversee the production process, ensuring that each step is executed with precision and care. Their expertise and attention to detail are essential in achieving the high-quality standards that consumers have come to expect. Additionally, many factories invest in training and development programs for their employees, fostering a culture of continuous learning and improvement.

The Future of Lipstick Tubes

Looking ahead, the future of lipstick tubes is bright and full of potential. As consumer preferences continue to evolve, factories will need to stay agile and adaptable, embracing new technologies and trends to stay relevant. We can expect to see even more sustainable and eco-friendly options, as well as an increased focus on customization and personalization. Additionally, with the rise of digital beauty and virtual try-on technologies, lipstick tubes may even evolve to incorporate smart features that enhance the shopping experience for consumers.

In conclusion, the lipstick tube factory is a vibrant and dynamic space where creativity, innovation, and craftsmanship come together to create tiny wonders that inspire and delight. From the initial spark of inspiration to the final product in the hands of the consumer, the journey is filled with color, precision, and a passion for making beauty accessible to all. As the beauty industry continues to evolve, we can only imagine the exciting new possibilities that await in the world of lipstick tubes.